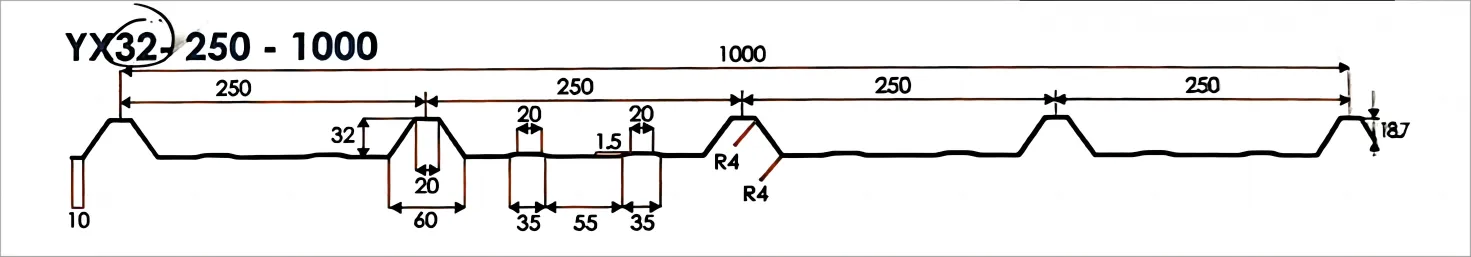

YX32-250-1000 Type Roof Panel Roll Forming Machine

Roofing system roll forming machine has a big range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile panel, step glazed tile, metal deck panel, standing seam panel, ridge cap, rain gutter, double layer/ two layer, K span panel and ridge cap machine. Its products are widely used in roof and wall system in workshop construction and housing construction. The normal machinable thickness range of our roof panel roll forming machine is 0.4mm-0.8mm, working raw material is Aluminum, PPGI, Galvanized steel, Galvalume steel etc. We design the machine according to your drawing, specially the pitch and height of each wave.

| Name | Description |

| Machinable Material : | Galvanized Coil PPGI,Alumzic 0.4-0.8mm |

| Yield strength : | 250 - 550 Mpa |

| Tensil stress : | 350 Mpa-550 Mpa |

| Nominal forming speed(M/MIN): | 0-12m/min |

| Forming station : | About 18 stations |

| Decoiler : | Manual decoiler |

| Driving system : | Chain drive |

| Machine structure: |

Roof panel station |

| Power supply : |

380V 50Hz |

| 1. | 5 tons manual decoiler | 1 set |

| 2 | Main roll forming machine | 1 set |

| 3 | Hydrualic cutting | 2 unit |

| Note:According to clients' requirement,no PLC control system and Hydraualic station. | ||

This machine is used to form the pre-painted sheet/GI material to various roofing of the projects such as sports center,exhibition center, subway project, airport and stadium etc.

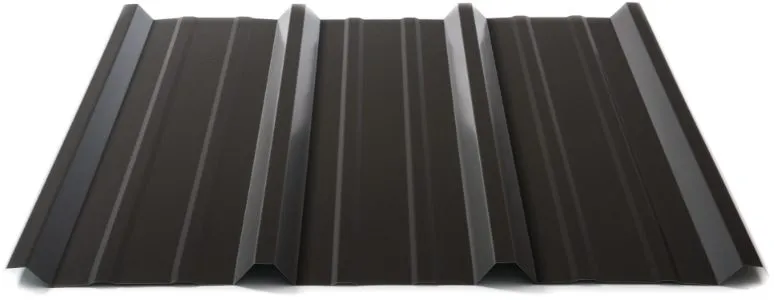

YX-32-250-1000 Panel is an economical, structural, light gauge through-fastener roof and wall panel that is an excellent choice for commercial, industrial and agricultural applications.

If you want to know more details about this machine,please feel free to contact us!

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)