Expanding Production Capacity for Australia with Automated Roll Forming Solutions

17 Dec

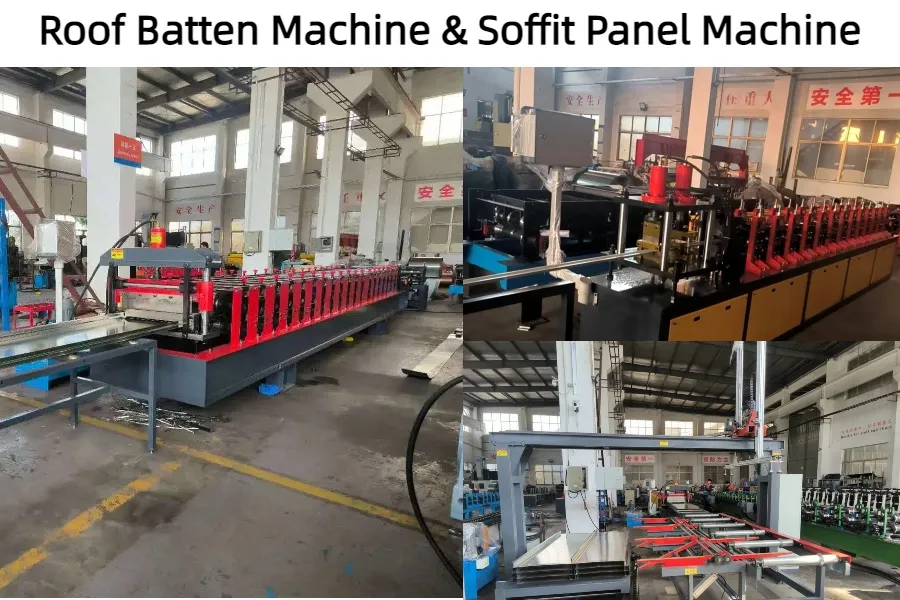

On December 17, our manufacturing facility reached another important shipment milestone as two roll forming machines were carefully loaded into containers for export to Australia. The shipment includes a roof batten roll forming machine and a soffit panel roll forming machine featuring an automatic stacking system. These machines are part of a larger order from an Australian customer who continues to expand production capacity through long-term cooperation with our company.

Australia remains a key destination for our roll forming machines, and we have successfully delivered numerous systems to customers throughout the country. From roofing accessories to exterior metal panels, our machines are widely used in projects that demand durability, precision, and efficient production. The current shipment further demonstrates the strong demand for automated roll forming solutions in the Australian market.

The customer receiving these machines has already purchased six machines from us in total. While this shipment covers two units, additional machines from the same order are still under production and will be shipped in the coming months. Such large-scale and phased orders highlight the customer’s confidence in our manufacturing capabilities and the performance of our equipment in real-world production environments.

Among the two machines being shipped, the roof batten roll forming machine stands out as a repeat purchase. This machine is the second identical unit ordered by the customer, following the successful operation of the first one. The decision to purchase the same model again was made to support production expansion without introducing unnecessary complexity. By using identical machines, the customer can maintain consistent product specifications, simplify maintenance, and ensure smooth coordination between production lines.

Roof battens play a vital role in metal roofing systems by providing structural support and ensuring proper alignment of roofing sheets. Our roof batten roll forming machine is engineered to produce accurate and consistent profiles, meeting the strict requirements of the Australian construction industry. Its robust structure and stable operation allow for long production runs, making it a reliable choice for manufacturers seeking to scale up output efficiently.

The second machine in the shipment, the soffit panel roll forming machine with auto stacker, reflects the growing importance of automation in modern manufacturing. Soffit panels are increasingly made from metal due to their durability, low maintenance, and clean appearance. However, handling finished panels manually can be labor-intensive and may increase the risk of surface damage, especially for coated or decorative panels.

To address these challenges, we equipped the soffit panel roll forming machine with an automatic flipping and stacking system. Once the panels are formed, the system automatically flips them into the correct orientation and stacks them neatly. To further protect the product surface, rubber material was added to the flipping device, effectively preventing scratches and marks during the handling process. This small but critical design detail helps ensure that the panels arrive at the next stage of packaging or installation in perfect condition.

The automatic stacker significantly reduces the need for manual intervention, improving workplace safety and production efficiency. It also allows for more consistent stacking, which is beneficial for storage, transportation, and downstream processing. For customers aiming to modernize their production lines, such automation features offer long-term value and operational advantages.

Throughout the loading process on December 17, our technical and logistics teams worked closely together to ensure that all machines were properly inspected, protected, and secured inside the containers. Exporting equipment to Australia requires careful attention to packaging and shipping standards, and every detail was handled according to established procedures.

This shipment represents more than just the delivery of machines; it is a reflection of a long-term partnership built on trust, quality, and continuous improvement. As more machines from this order are prepared for shipment, we remain committed to supporting our Australian customers with advanced roll forming technology, customized solutions, and reliable after-sales service.

Looking ahead, we are confident that our cooperation with customers in Australia will continue to grow, driven by innovation, automation, and a shared focus on efficient and sustainable production.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor