Highway Guardrails: The Unsung Heroes of Road Safety – A Deep Dive into 2-Wave & 3-Wave Systems

06 Sep

Highway Guardrails: The Unsung Heroes of Road Safety –

A Deep Dive into 2-Wave&3-Wave Systems

Introduction: The First Line of Defense on the Road

Every time we travel on a highway, we are surrounded by silent, vigilant guardians. They are not made of flesh and blood, but of galvanized steel, meticulously engineered to save lives. Highway guardrails, or safety barriers, are one of the most crucial yet overlooked elements of road infrastructure. Their primary purpose is not to prevent accidents but to minimize their severity. They are designed to absorb impact, redirect errant vehicles, and prevent catastrophic outcomes like cross-median collisions or plunges down embankments.

Among the various types, the Thrie-Beam (3-wave) and W-Beam (2-wave) guardrails are the most common. Understanding their differences is key to appreciating the complex science of road safety. This blog serves as your ultimate guide to these life-saving systems.

Chapter 1: The Physics of a Crash – Why Guardrails Work

Before we compare the two types, it's essential to understand how they function. A guardrail is not a rigid wall. Its job is to be dynamically strong. When a vehicle impacts, the system is designed to:

-

Capture: The vehicle's bumper or side makes contact with the rail face.

-

Redirect: The rail and its posts deform and buckle in a controlled manner, converting the vehicle's kinetic energy into deformation energy and friction. This slows the vehicle down and guides it along a safer path, parallel to the rail.

-

Contain: The system must be strong enough to prevent the vehicle from penetrating through or vaulting over the barrier, especially critical for larger, heavier vehicles.

This controlled deceleration and redirection are what prevent sudden stops and save lives.

Chapter 2: Meet the Contenders – W-Beam (2-Wave) vs. Thrie-Beam (3-Wave)

The "waves" refer to the number of ribs or corrugations pressed into the steel beam. This corrugation isn't for aesthetics; it dramatically increases the beam's stiffness and strength along its length, much like the flanges on an I-beam.

The W-Beam (2-Wave) Guardrail:

-

Profile: Features two back-to-back, rounded "W" shapes, creating a distinct two-rib profile.

-

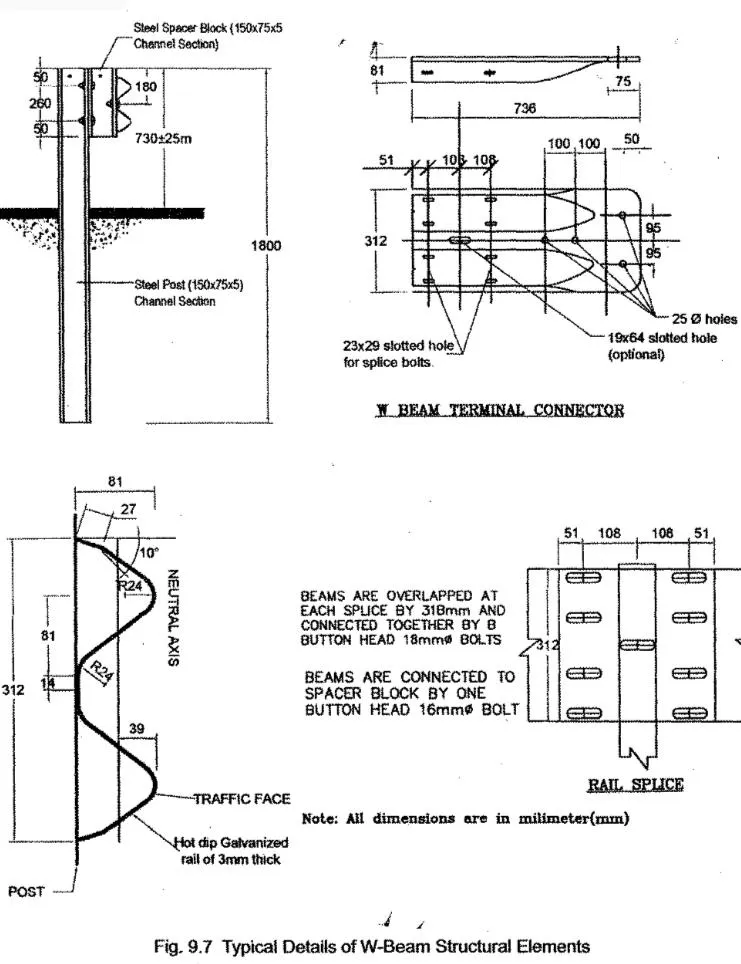

Material & Size: Typically made from galvanized steel. The standard size is 12-gauge (approx. 2.66 mm thick) with a 312 mm (12.25-inch) depth.

-

Function: This is the workhorse of the guardrail world. It is designed as a semi-rigid barrier. It is intended to deflect (bend and move) significantly upon impact to absorb energy. This deflection must be carefully managed to prevent the rail from "pocketing" a vehicle or causing it to roll over.

-

Ideal Application: The W-beam is the default choice for the vast majority of situations. It is perfectly suited for:

-

Dividing medians on standard highways.

-

Roadside applications where the terrain behind the rail is relatively flat and clear (allowing for the necessary deflection distance).

-

Redirecting passenger vehicles and light trucks.

-

-

Limitations: Its capacity is limited. It is less effective for containing heavier vehicles (like semi-trucks and buses) or for high-angle, high-speed impacts. In these cases, the vehicle may break through or roll over the barrier.

The Thrie-Beam (3-Wave) Guardrail:

-

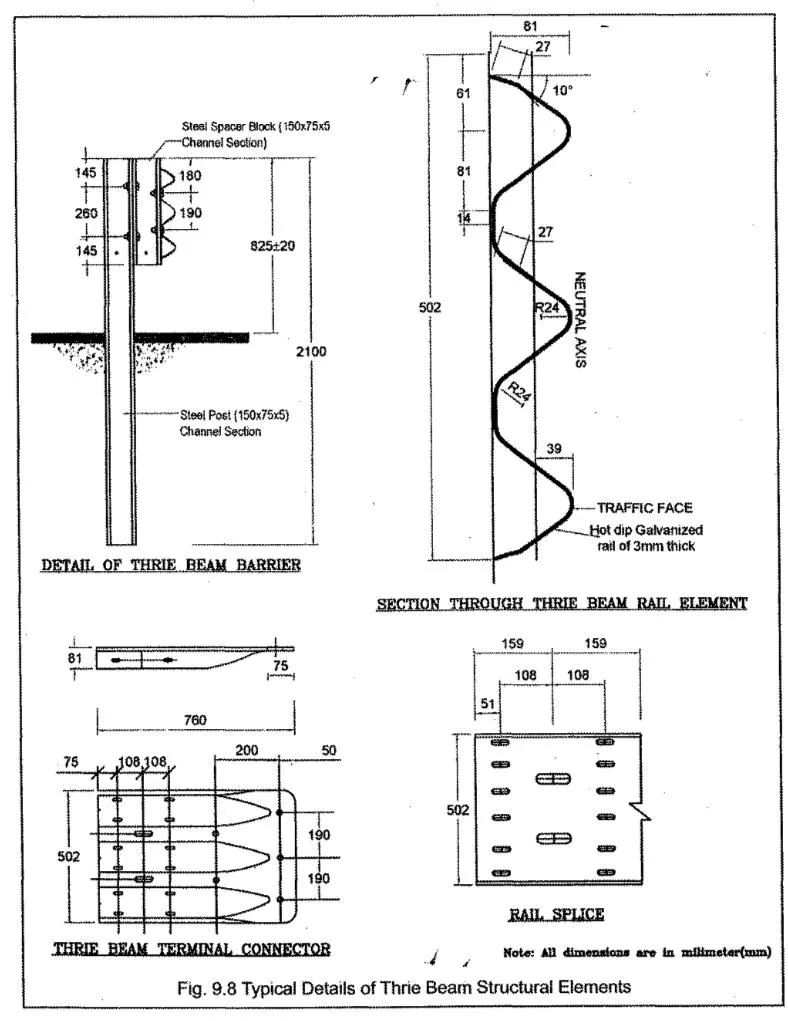

Profile: Features an extra rib, creating a "triple-wave" or "triple-corrugated" profile.

-

Material & Size: Also made from galvanized steel but is typically larger and heavier. It is often 10-gauge (approx. 3.43 mm thick) with a 483 mm (19-inch) depth. The extra metal and the third rib make it substantially stronger and stiffer.

-

Function: The Thrie-Beam is a semi-rigid to rigid barrier, but it is significantly stronger than the W-beam. It is designed to deflect less upon impact, providing a higher level of containment.

-

Ideal Application: The Thrie-Beam is the heavy-duty solution for high-risk areas. It is specified for:

-

High-volume, high-speed roadways like freeways and interstates.

-

Areas with limited "clear zone" (the recoverable area beyond the rail) where less deflection is critical (e.g., near steep drops, bridges, or deep water).

-

Containing larger, heavier vehicles. Its design makes it far more effective at preventing heavy trucks from breaking through.

-

Sharp curves where impact angles are more severe.

-

-

Limitations: It is more expensive due to the increased material and heavier posts required. It is also more complex to install correctly.

Chapter 3: A Side-by-Side Comparison

| Feature | W-Beam (2-Wave) | Thrie-Beam (3-Wave) |

|---|---|---|

| Profile | Two corrugations / ribs | Three corrugations / ribs |

| Strength & Stiffness | Good (Semi-Rigid) | Excellent (Semi-Rigid to Rigid) |

| Deflection | Higher | Lower |

| Containment Level | Standard passenger vehicles, light trucks | Heavy trucks, buses, high-energy impacts |

| Cost | Lower | Higher (more steel, heavier posts) |

| Primary Application | Standard highways, medians, clear zones | High-risk areas, limited clear zones, sharp curv |

Application:

Conclusion: A Matter of Right-Tool-for-the-Right-Job

The choice between a 2-wave and a 3-wave guardrail is never arbitrary. It is a calculated engineering decision based on traffic volume, average vehicle speed, the types of vehicles using the road, and the geometry of the roadside environment. While the W-beam efficiently handles the majority of scenarios, the Thrie-Beam is the critical upgrade for our most dangerous and demanding roads. Together, these two systems form an adaptable, life-saving network that protects millions of motorists every day.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor