The Ultimate Guide to Scaffolding Planks: Safety, Materials, and Choosing the Right Decking

06 Sep

The Ultimate Guide to Scaffolding Planks: Safety, Materials, and Choosing the Right Decking

Introduction: The Unsung Hero of Construction

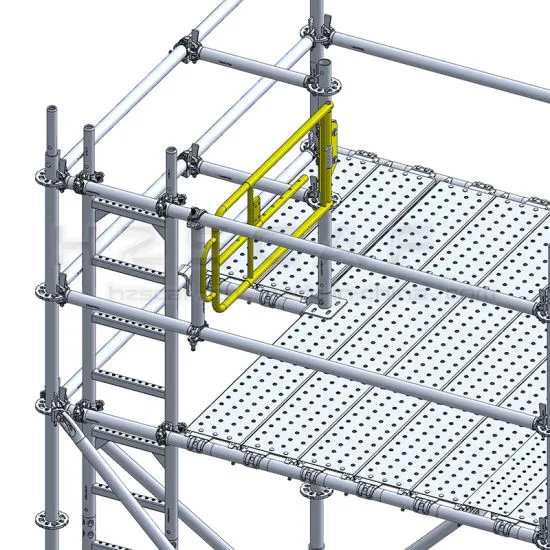

When we picture a construction site, our eyes are often drawn to the towering skeletal structure of the scaffolding itself. But the true workhorse, the platform upon which every worker, tool, and material stands, is the humble scaffolding plank. Often an afterthought, the choice of decking is one of the most critical safety and efficiency decisions on any project. A failure here isn't just an equipment malfunction; it's a direct threat to human life.

This guide delves deep into the world of scaffolding planks, exploring the different types, their compliance with stringent Australian standards, and how to select the right decking for your project to ensure a safe, productive, and compliant worksite.

Chapter 1: Types of Scaffolding Planks – Materials Matter

Not all planks are created equal. The material choice impacts weight, durability, cost, and most importantly, safety.

1. Traditional Solid-Sawn Timber Planks:

-

Description: The classic choice, typically made from hardwoods like Victorian Ash or imported woods like Karri.

-

Pros: Naturally high friction surface, readily available, and can be cut to size on-site.

-

Cons: Heaviest option, leading to higher labour costs for handling. Susceptible to warping, cracking, and splitting over time. Requires constant inspection for defects. Variable quality and strength. Can be a fire hazard.

2. LVL (Laminated Veneer Lumber) Planks:

-

Description: An engineered wood product made by bonding thin wood veneers under heat and pressure.

-

Pros: Much more consistent and predictable strength than sawn timber. Higher load-bearing capacity for the same dimension. Less prone to warping and shrinking. Lighter than solid hardwood.

-

Cons: More expensive than traditional timber. Ends must be sealed to prevent moisture ingress. Can be slippery when wet if not treated.

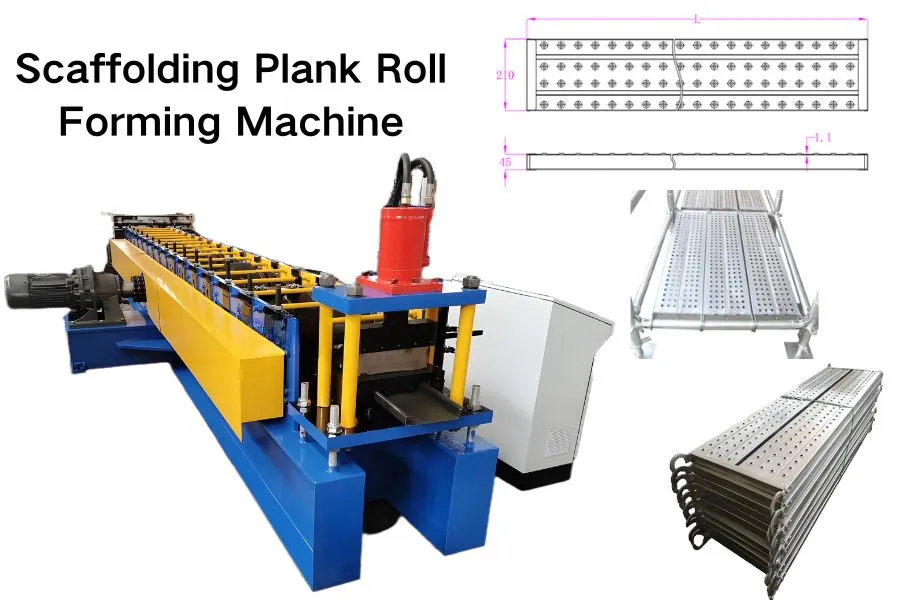

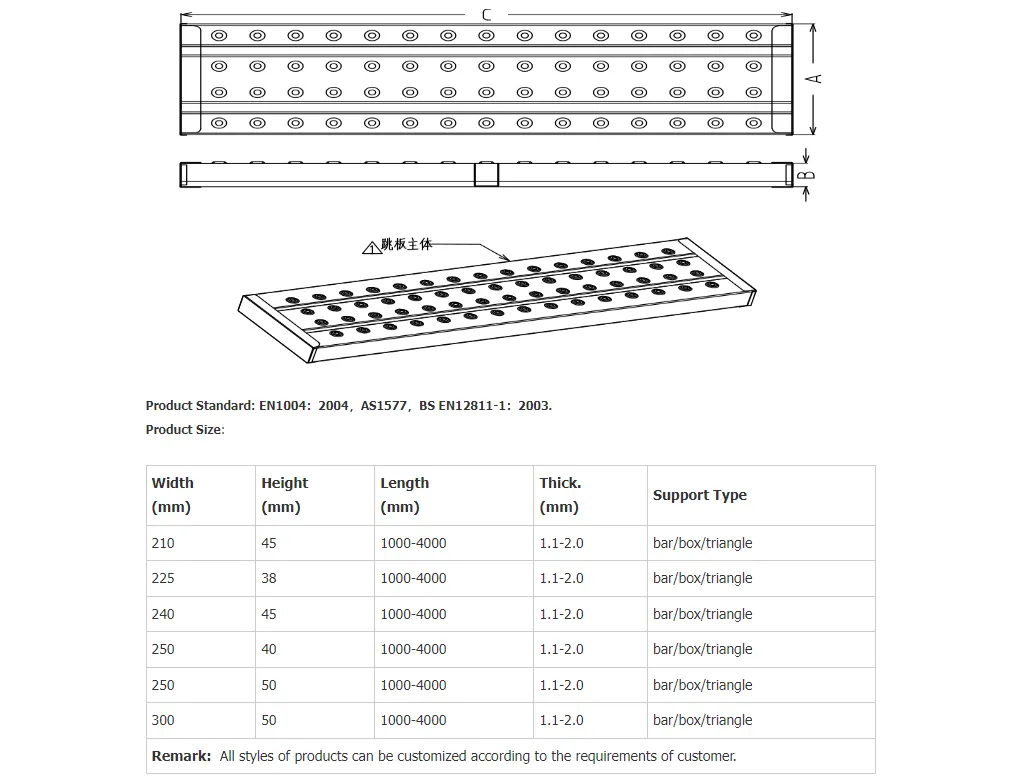

3. Steel & Aluminum Planks (The Modern Standard):

-

Description: These are not solid metal sheets but are instead manufactured from high-tensile steel or aluminium alloy using a roll forming process (which we will explore in Blog 2). They feature a profiled design for strength and a perforated or expanded metal surface.

-

Pros:

-

Safety: Incredibly strong and consistent. Non-combustible. The perforated surface provides excellent slip resistance, even in wet or oily conditions.

-

Durability: Impervious to rot, insects, and moisture. They have the longest lifespan of any plank type, withstanding extreme abuse.

-

Lightweight: Especially aluminium, which can be up to 60% lighter than timber, drastically reducing worker fatigue and handling time.

-

Compliance: Easily designed to meet and exceed Australian Standards (AS/NZS 1577) with clear load rating stamps.

-

-

Cons: Higher initial investment cost. Cannot be modified on-site with a saw.

.webp)

Chapter 2: The Golden Rule – Compliance with Australian Standards (AS/NZS 1577)

In Australia, scaffolding plank safety is governed by AS/NZS 1577:2013 Scaffold decking components. This standard is not a guideline; it is a mandatory requirement. Here’s what it dictates:

-

Load Ratings: Planks must be clearly marked and certified for their Safe Working Load (SWL). Common ratings include:

-

Light Duty (LD): 0.75 kPa (e.g., for light maintenance work)

-

Medium Duty (MD): 1.5 kPa (standard general construction)

-

Heavy Duty (HD): 2.25 kPa (for areas with heavy material storage)

-

Special Duty (SD): 3.0 kPa+ (for specific high-load applications)

-

-

Testing and Certification: Manufacturers must rigorously test their products to prove they can withstand at least four times the SWL (Factor of Safety of 4:1) without failure.

-

Marking: Every plank must be permanently and legibly marked with the manufacturer’s name, the SWL rating, and the standard it complies with (e.g., "AS/NZS 1577 HD").

-

Inspection: Planks must be inspected before each use and formally recorded in a logbook. Timber planks with excessive deflection, large knots, splits, or rot must be immediately taken out of service.

Chapter 3: How to Choose the Right Scaffolding Plank for Your Project

Selecting the right plank is a balance of safety, practicality, and economics.

-

Assess the Load Requirements: What will be on the platform? Just workers, or also stacks of bricks, bags of mortar, and equipment? Always err on the side of a higher SWL.

-

Consider the Project Duration: For a long-term project (e.g., a high-rise build), the durability and reusability of steel or aluminium planks make them far more economical over time despite the higher upfront cost. For a very short job, timber might suffice.

-

Evaluate the Environment: Is the site coastal (corrosive salt air)? Is it a chemical plant? Metal planks, particularly aluminium or hot-dip galvanized steel, are the only choice for harsh environments where timber would quickly degrade.

-

Factor in Handling and Logistics: How often will the planks be moved? The weight savings of aluminium planks can lead to significant reductions in crane time, labour hours, and the risk of musculoskeletal injuries for workers.

-

Prioritize Safety Culture: Slip-resistant metal planks with consistent performance actively contribute to a safer worksite. They demonstrate a commitment to investing in the best protection for your workforce.

Conclusion: An Investment in Safety and Efficiency

The scaffolding plank is a foundational element of construction safety. Moving away from variable and degradable timber to engineered LVL or, ideally, modern roll-formed metal planks is a clear step towards a safer, more efficient, and more compliant future. By understanding the types, standards, and selection criteria, project managers, supervisors, and safety officers can make an informed decision that protects their most valuable asset: their people.