Servo Following Cutting Corrugated Roof Panel Roll Forming Machine

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

description1

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Product description

A High-speed, Fly-Cutting, Gearbox-Driven Corrugated Roof Panel Roll Forming Machine is a specialized piece of industrial equipment that uses a series of precision rollers to continuously form flat metal coils into corrugated roofing panels at a high rate of speed. This type of machine is defined by its use of a flying shear and gearbox drive, both of which are high-performance features.

These machines operate with high speed and efficiency. The process involves uncoiling metal, shaping it with rollers, cutting to length with a flying shear while the line is in motion, and stacking. Key features include high speed, reaching up to 30 meters per minute, precise fly-cutting, and a durable gearbox drive suitable for thicker materials.

Parameter Specification

| Item | value |

| Production Capacity | 15m/min |

| Rolling thickness |

0.3-0.8mm galvanized steel |

| Feeding width | 1220mm |

| Roller station | About 18-20 stations |

| Tile Type |

Colored corrugated |

| Main motor | 7.5KW |

| Hydraulic station |

4KW |

| Way Of Drive |

Chain driven |

| Materila of cutting |

Cr12Mov |

Machine List:

| 5 tons passive decoiler | 1 set |

| Main roll forming Machine | 1 set |

| Control box | 1 set |

| Hydraulic station | 1 set |

| Hydraulic Servo Cutting | 1 unit |

| Out table | 1 unit |

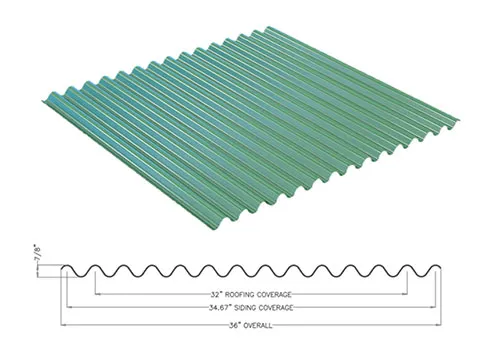

Profile Drawing

Application

Corrugated roof panels are characterized by their signature wavy ridges, which create a strong, lightweight, and durable roofing solution. Panels are available in several different materials, with the best choice depending on the project's purpose and budget.