Scaffolding Plank Roll Forming Machine

17 Jul

A scaffolding plank is a long, flat piece of material, typically made of steel, aluminum, or wood, that is used as a walking or working platform in construction and maintenance activities.

Scaffolding planks are critical components of scaffolding systems, providing safe and sturdy platforms for workers to perform tasks efficiently and securely at elevated heights.

The use of steel scaffold plank avoids the disadvantage of heavy water absorption and extreme slippery caused by rain on wooden scaffold planks. Sussman Machinery is a leading roll forming machine manufacturer to make the scaffolding plank roll forming machine, and we offer OEM service. Here I introduce one kind of scaffolding plank roll forming machine.

A scaffolding steel plank roll forming machine is a specialized piece of equipment used in the manufacturing of steel planks that are commonly used in scaffolding systems. Here's how it generally works:

- Decoiler: to load the coil

- Punching: hydraulic punching or press machine punching

- Material Feeding: The machine starts with feeding coils of steel strip or sheet into the machine. These coils are unwound and fed into the roll forming section.

- Roll Forming: The steel strip passes through a series of rollers that gradually shape it into the desired profile of the steel plank. The rollers are strategically designed to bend and form the steel without compromising its structural integrity.

- Cutting: Once the steel strip has been formed into the plank shape, a cutting mechanism cuts the plank to the required length. This is usually done by a flying saw or a stationary shear depending on the design of the machine.

- Stacking or Packaging: After cutting, the individual planks are either stacked or packaged according to the manufacturer's requirements. This could involve stacking them on pallets for easy transport and storage.

- Control System: Modern roll forming machines are equipped with computerized control systems that monitor and adjust the speed of the machine, the dimensions of the planks, and other parameters to ensure consistent quality and efficiency.

The output of these machines is typically high-volume and tailored to meet specific dimensional and strength requirements for scaffolding applications. These steel planks are crucial components in construction and are designed to provide a safe platform for workers and materials at various heights.

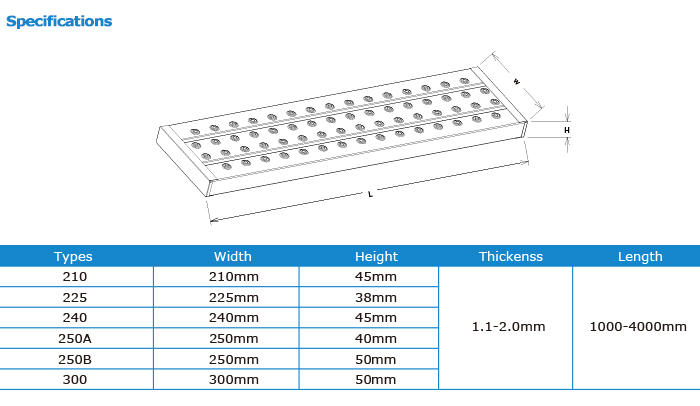

Profile Drawing:

The thickness is 1.2-2.0mm, sizes are 210mm, 225mm, 240mm, 250mm, 300mm. The raw material is Q195-Q335.

Some Samples:

Application:

.png?x-oss-process=image/resize,w_100/quality,q_100)