The Role of Israel Trunking Boxes in Revolutionizing Continuous Casting Processes

10 Mar

The Role of Israel Trunking Boxes in Revolutionizing Continuous Casting Processes

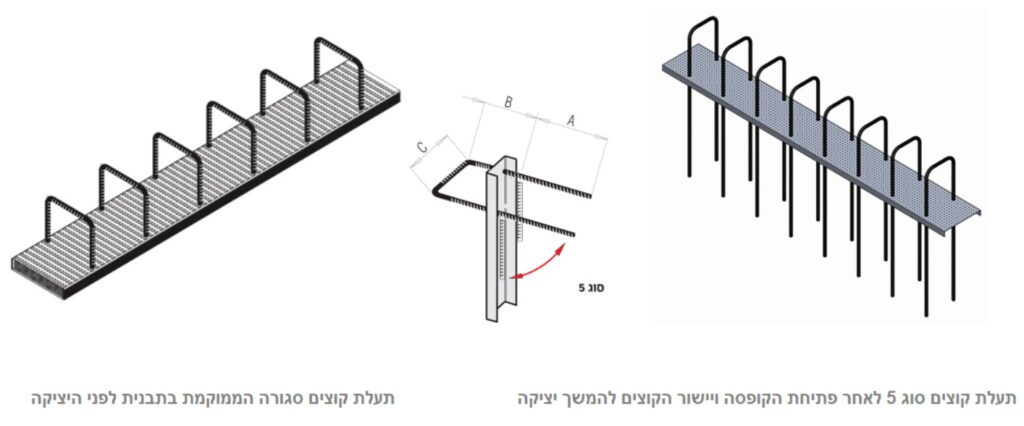

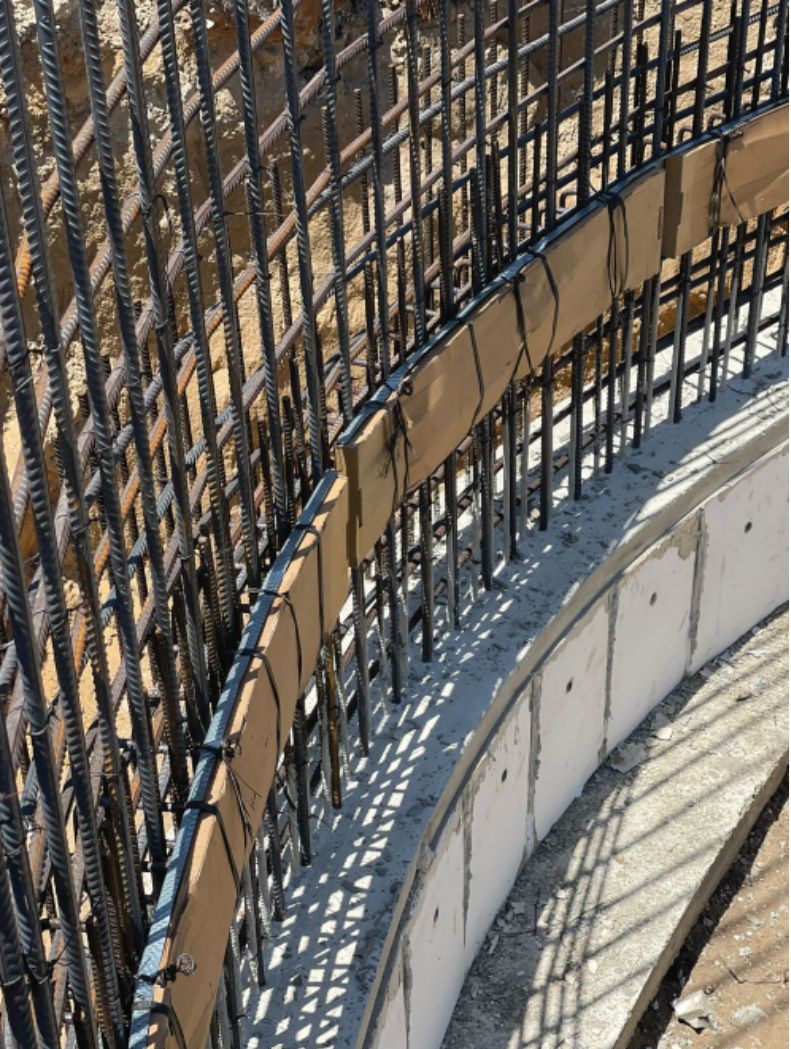

Continuous casting is a critical process in the metallurgical industry, enabling the production of high-quality metal products with improved efficiency and reduced waste. One of the key components that ensure the success of continuous casting is the trunking box. In recent years, Israel has emerged as a leader in the design and manufacturing of advanced trunking boxes, which are now widely used in steel plants and foundries worldwide. In this blog, we’ll explore the importance of trunking boxes in continuous casting and how Israeli innovations are setting new standards in the industry.

What is a Trunking Box?

A trunking box, also known as a tundish, is a crucial component in the continuous casting process. It acts as a reservoir that holds molten metal and controls its flow into the casting mold. The trunking box ensures a consistent and steady supply of molten metal, which is essential for producing uniform and defect-free metal products.

Why Trunking Boxes are Essential

-

Flow Control: Trunking boxes regulate the flow of molten metal, preventing turbulence and ensuring smooth operation.

-

Temperature Maintenance: They help maintain the temperature of the molten metal, reducing the risk of solidification before it reaches the mold.

-

Impurity Removal: Modern trunking boxes are designed to trap impurities and slag, ensuring cleaner metal output.

-

Efficiency: By optimizing the flow and reducing waste, trunking boxes improve the overall efficiency of the continuous casting process.

Israeli Innovations in Trunking Box Design

Israel has become a hub for advanced engineering solutions, and its contributions to the metallurgical industry are no exception. Israeli companies have developed trunking boxes that incorporate cutting-edge materials and technologies, offering several advantages:

-

Advanced Refractory Materials: Israeli trunking boxes use high-quality refractory materials that withstand extreme temperatures and corrosive environments, ensuring longer lifespans and reduced maintenance costs.

Caption: High-quality refractory materials used in Israeli trunking boxes. -

Smart Monitoring Systems: Some Israeli trunking boxes are equipped with sensors and IoT-enabled systems that monitor temperature, flow rate, and metal quality in real-time. This data helps operators make informed decisions and optimize the casting process.

-

Customizable Designs: Israeli manufacturers offer customizable trunking boxes tailored to the specific needs of different industries, whether it’s steel, aluminum, or copper production.

-

Sustainability: Israeli trunking boxes are designed with sustainability in mind, reducing energy consumption and minimizing waste during the continuous casting process.

Applications of Israeli Trunking Boxes

Israeli trunking boxes are used in a wide range of industries, including:

-

Steel Production: For casting billets, slabs, and blooms.

-

Aluminum Manufacturing: For producing high-quality aluminum sheets and profiles.

-

Copper and Alloy Casting: For creating wires, rods, and other components.

Conclusion

The continuous casting process relies heavily on the performance of trunking boxes, and Israeli innovations have taken this critical component to the next level. With advanced materials, smart technologies, and a focus on sustainability, Israeli trunking boxes are helping manufacturers achieve higher efficiency, better product quality, and reduced environmental impact. As the demand for high-quality metal products continues to grow, the role of Israeli trunking boxes in the global metallurgical industry will only become more significant.

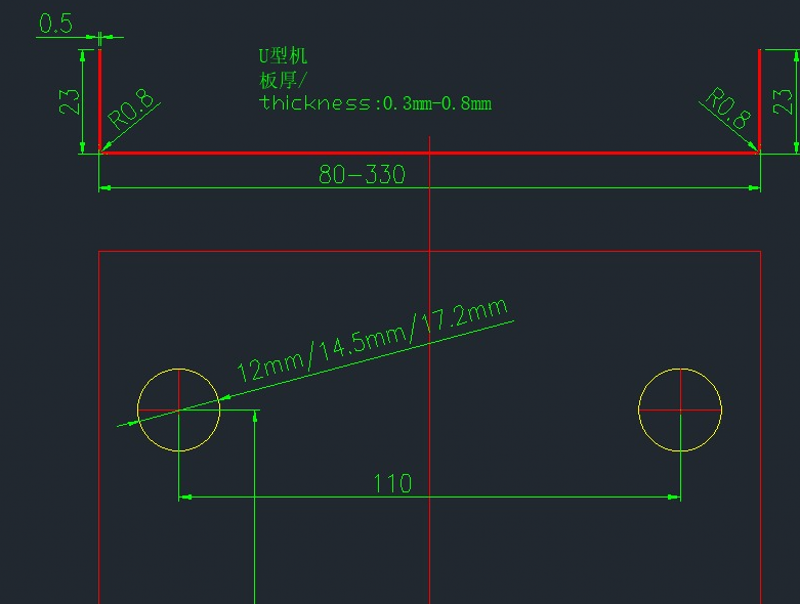

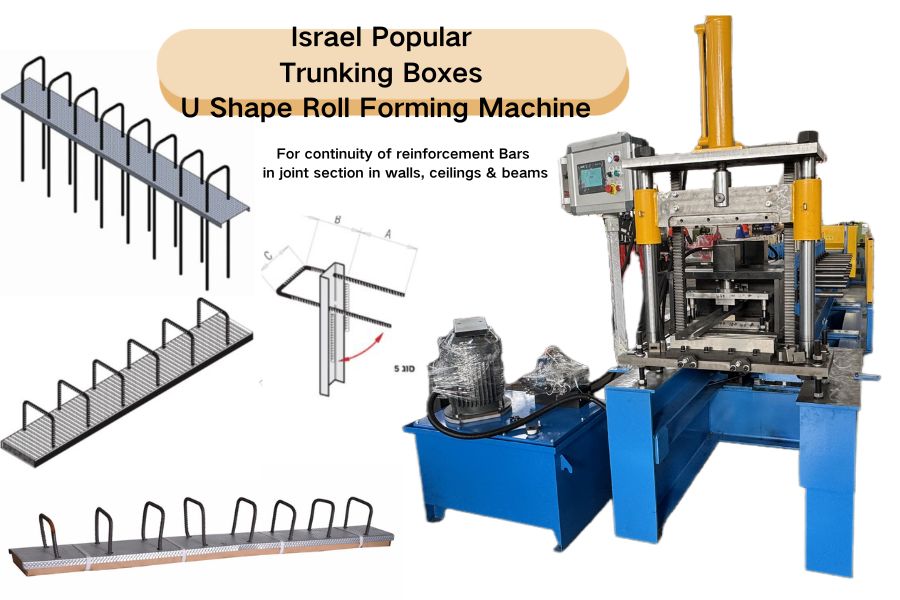

We have the machine to produce 80-300mm U channel box. If you are interested in, welcome to inquiry!