The Versatility of Multiple Sizes Light Steel Framing Machines in Modern Construction

10 Mar

The Versatility of Multiple Sizes Light Steel Framing Machines in Modern Construction

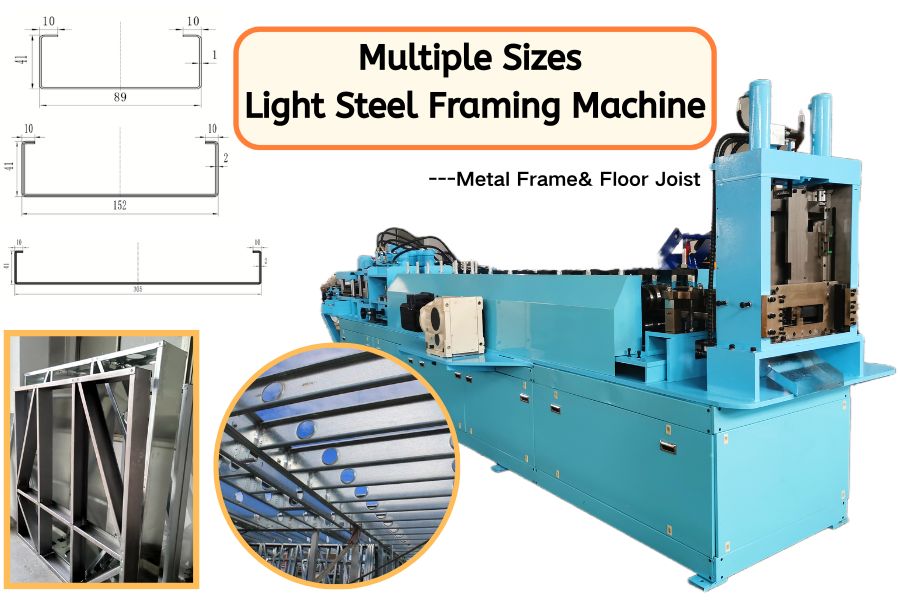

In the ever-evolving world of construction, efficiency, durability, and flexibility are key. One of the most significant advancements in recent years is the use of light steel framing machines that can produce metal frames and floor joists in multiple sizes. These machines have revolutionized the way buildings are constructed, offering a faster, stronger, and more sustainable alternative to traditional wood framing. In this blog, we’ll explore the benefits of light steel framing machines and how they are transforming the construction industry.

What is a Light Steel Framing Machine?

A light steel framing machine is a specialized piece of equipment designed to produce metal frames and floor joists from roll-formed steel. These machines can create frames and joists in various sizes, making them suitable for a wide range of construction projects, from residential homes to commercial buildings.

Advantages of Light Steel Framing Machines

-

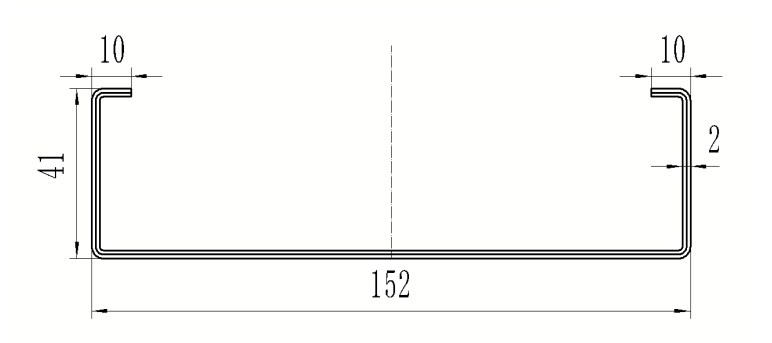

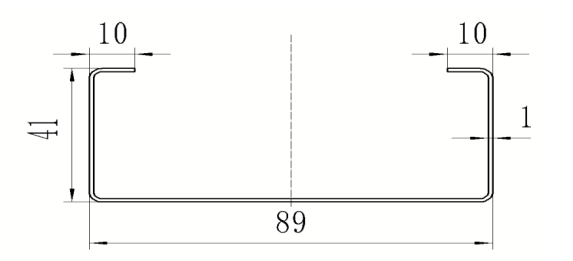

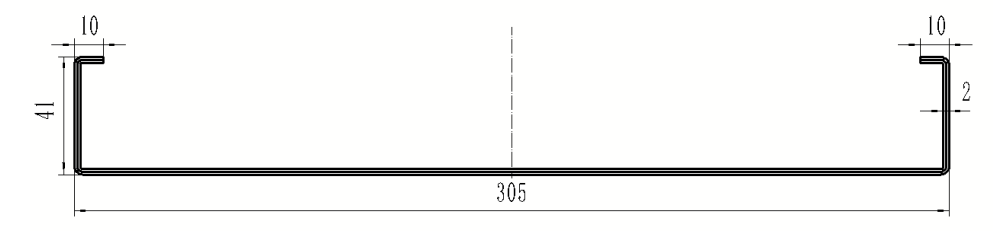

Multiple Sizes and Customization: One of the standout features of these machines is their ability to produce frames and joists in multiple sizes. This flexibility allows builders to customize the framing to meet the specific needs of each project.

-

Strength and Durability: Steel frames are significantly stronger and more durable than traditional wood frames. They are resistant to warping, cracking, and termite damage, ensuring the longevity of the structure.

-

Speed and Efficiency: Light steel framing machines can produce frames and joists at a much faster rate than traditional methods. This speeds up the construction process, reducing labor costs and project timelines.

-

Sustainability: Steel is a recyclable material, making it an environmentally friendly choice. Additionally, the precision of light steel framing machines minimizes waste during production.

Applications of Light Steel Framing Machines

Light steel framing machines are used in a variety of construction applications, including:

-

Residential Homes: For framing walls, roofs, and floors.

-

Commercial Buildings: For creating structural frameworks and partitions.

-

Industrial Facilities: For constructing durable and fire-resistant structures.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

The Role of Metal Frames and Floor Joists

Metal frames and floor joists are essential components of any building structure. They provide the necessary support and stability, ensuring the safety and integrity of the building. Light steel framing machines produce these components with precision and consistency, resulting in high-quality frames and joists that meet industry standards.

Case Study: A Successful Implementation

A construction company in the United States recently adopted light steel framing machines for a large residential project. The results were impressive:

-

Time Savings: The project was completed 30% faster than similar projects using traditional framing methods.

-

Cost Efficiency: Reduced labor costs and material waste led to significant savings.

-

Customer Satisfaction: The homeowners were delighted with the durability and quality of the steel-framed structure.

Conclusion

Light steel framing machines are a game-changer in the construction industry. Their ability to produce multiple sizes of metal frames and floor joists with precision and efficiency makes them an invaluable tool for modern builders. As the demand for stronger, faster, and more sustainable construction methods continues to grow, light steel framing machines will undoubtedly play a central role in shaping the future of construction.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)