Versatile Hat Purlins: Dimensions, Applications, and the Efficiency of Hat Purlin Roll Forming Machines

25 Oct

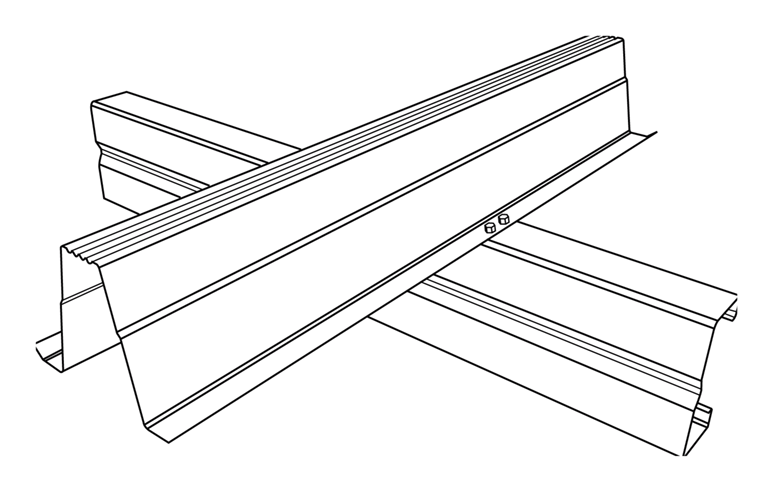

Introduction to Hat Purlins in Modern Construction

As building techniques evolve, the materials and components used in construction adapt to meet new demands. Hat purlins are one such innovation, valued for their lightweight, high-strength profile, making them a practical choice in various structural applications.

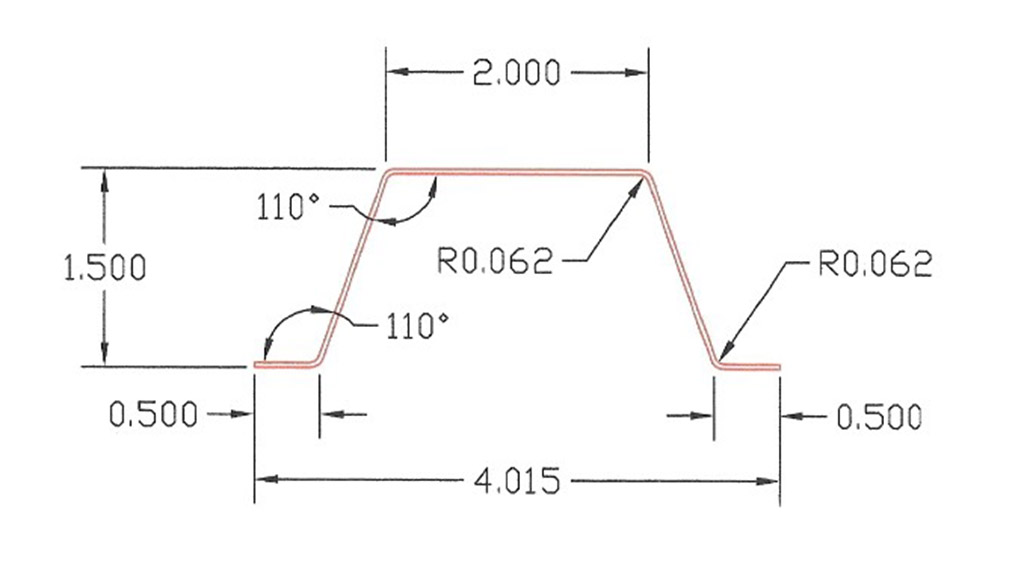

Hat Purlin Sizes and Thickness Options

Hat purlins come in standard sizes and thicknesses, tailored to fit different structural needs. These dimensions typically include:

- Widths from 2 to 6 inches, depending on the span and load requirements.

- Heights from 1 to 4 inches, giving extra flexibility in different applications.

- Thicknesses from 0.04 to 0.12 inches, selected based on the load-bearing expectations of the project.

For instance, thicker hat purlins (around 0.12 inches) are ideal for large industrial buildings where heavy-duty support is needed. In contrast, thinner purlins are suitable for residential projects, where lighter frameworks are often preferred.

Applications of Hat Purlins

The versatility of hat purlins makes them ideal for a range of construction needs. Key applications include:

-

Roofing Systems: Hat purlins are widely used to support roofing panels in both industrial and residential buildings. Their structure provides stability and durability, ensuring the longevity of roofing systems.

-

Wall Framing: Hat purlins offer excellent support for wall cladding, particularly in industrial settings where walls require strong framing that’s lightweight and durable.

-

Partitions and Interior Framework: Hat purlins are also valuable in interior partitions, providing sturdy and lightweight frameworks for internal walls and partitions in commercial and residential buildings.

-

Industrial and Agricultural Buildings: The strength and durability of hat purlins make them ideal for warehouses, barns, and other large-scale buildings where structural support is crucial.

Efficiency of Hat Purlin Roll Forming Machines

Hat purlins are manufactured using specialized hat purlin roll forming machines, which are designed to produce these components quickly and consistently. Equipped with automated controls, these machines allow adjustments in size, thickness, and profile, giving manufacturers the flexibility to create custom hat purlins based on project specifications.

Key Benefits of Hat Purlin Roll Forming Machines:

- Automated Adjustments: Operators can set specific parameters, such as width and thickness, to meet project requirements.

- High Output Rate: These machines operate at high speeds, ensuring large-scale production for construction projects.

- Cost Efficiency: By optimizing material usage and reducing labor costs, roll forming machines make hat purlin production economical and scalable.

Conclusion

Hat purlins are a valuable component in modern construction, providing strength and flexibility in both commercial and residential applications. The efficiency and precision of the hat purlin roll forming machine further enhance their appeal by enabling consistent production of high-quality hat purlins that meet specific construction needs. With adaptable dimensions and robust applications, hat purlins are likely to remain a staple in construction frameworks for years to come.