Galvanized Steel Hat Channel Omega Profile Roll Forming Machine

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

| Feeding material | 0.4-1.2mm galvanized steel, color steel. Aluzinc |

| Profile size | 64*22mm;80*25mm |

| Roller Station: | 12 Steps |

| Cutting System | Hydraulic stop cutting and non stop cutting |

| Hydraulic Pump Station | 5.5KW |

| Production Speed |

8-12m/min or 0-30m/min(optional select) |

| Main motor | 5.5KW |

| Non-stop Cut System |

PLC Siemens |

| 3 tons decoiler | 1 set |

| Main roll forming machine | 1 set |

| Control box | 1 set |

| Hydraulic station | 1 set |

| Hydraulic Cutting | 1 unit |

| Out table | 1 unit |

Furring channel machine is used to plaster board, gypsum board and other decorative finishes lightweight board made of non-load-bearing walls and roof of the building style decoration, a variety of decorative building roof shape, inside and outside the building wall and ceiling scaffolding base material.Products made by this machine are suitable to use in hotels, theaters, shopping malls, factories, office buildings, old building renovation, interior decoration settings, roof and other places.

Material for this machine is galvanized steel plate, snowflake plate and cold steel plate,we can according to customer design, manufacture different specifications of cold-formed.

In Drywall system and drywall partition system, we could provide roll forming machine as following: 1. Metal stud roll forming machine 2. Metal track roll forming machine 3. Conner bead (Angle bead) roll forming machine

According to customers’ profile drawings Customized.

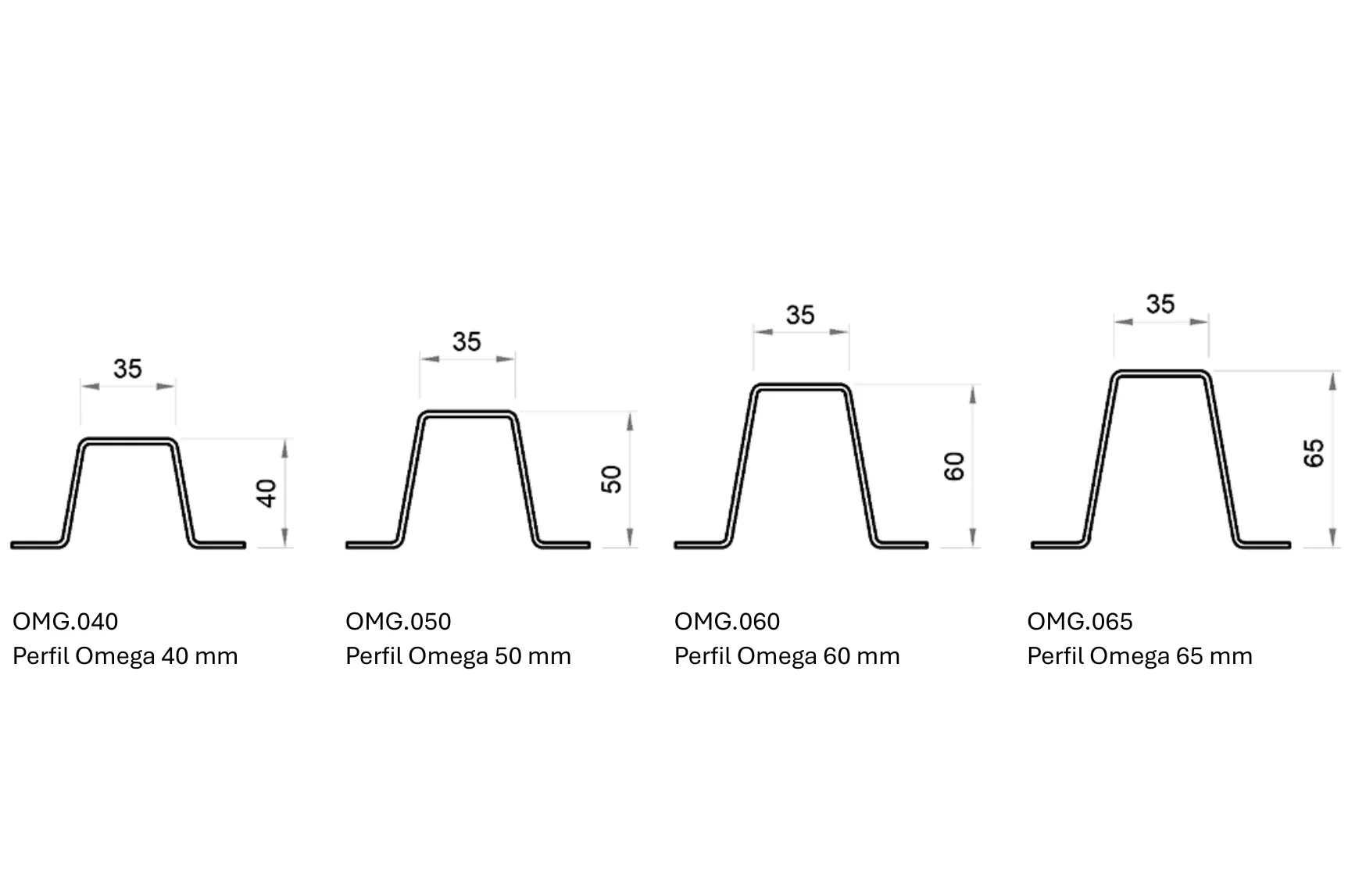

A Omega channel is a cold-formed steel framing component used in construction for walls, ceilings, and roofs. Named for its "hat-shaped" cross-section, it is also known as furring channel. It creates a space, or "furring," between a finished surface and the underlying framing to provide a level plane for attachment and improve the assembly's performance.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)